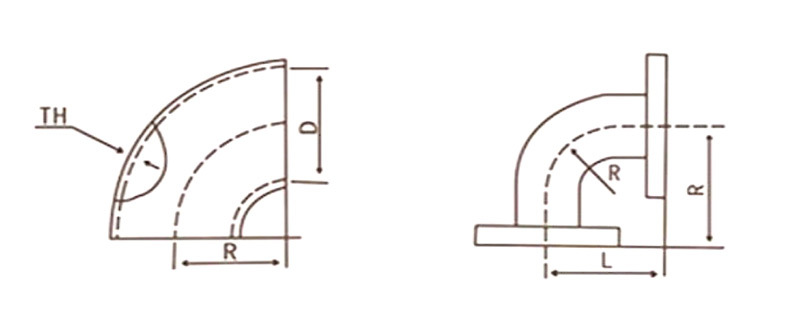

FRP elbow

- Commodity name: FRP elbow

- Detailed description

-

Product Description

Bends below DN800mm are formed by winding as a whole, while large fiberglass elbows are formed by hand laying. KELIN fiberglass elbows have three structural forms: integral forming on the mold, semi mold split forming, and shrimp joint bending after prefabricated pipes.

1. The KELIN for the formation of the police body on the mold adopts the existing metal mold with a diameter below DN800, and is formed as a whole using the winding process using fiberglass raw materials.

2. Half mold split molding. Without relevant elbow molds, KELIN produces half elbow molds. After producing two half fiberglass elbows, they are spliced together to form a finished elbow product.

3. After prefabricating the pipeline, the shrimp joint is bent into shape. First, the corresponding specifications of fiberglass pipes are made, and then the pipes are cut into several sections and spliced into elbows. This molding method is mostly used under conditions where there is a certain stiffness requirement for fiberglass elbows, or when there is no ready-made mold and the cost of making the mold is relatively high.

Technical ParameterD

R

0.6MP

1.0MPa

1.6MPa

TH

L

TH

L

TH

L

10

15

5.5

115

5.5

115

5.5

115

15

22 5

5.5

122.5

5.5

122.5

5.5

122.5

20

30

5.5

130

5.5

130

5.5

130

25

37.5

5.5

137.5

5.5

137.5

5.5

137.5

32

48

5.5

148

5.5

148

5.5

148

40

60

5.5

160

5.5

160

5.5

160

50

75

5.5

175

5.5

175

5.5

225

65

97.5

5.5

197.5

5.5

247.5

55

257.5

80

120

55

270

5.5

280

5.5

320

100

150

5.5

300

5.5

330

9.4

400

125

187.5

5.5

387.5

55

417.5

9.4

487.5

150

225

55

425

9.4

505

10.9

595

200

300

2.1

520

98

660

12.9

800

250

375

9.4

655

10.4

798

15.2

995

300

450

9.4

750

13.3

950

17.3

350

525

9.8

925

15.8

1095

19.6

400

600

10.6

1020

16 8

23.8

450

675

13.0

1155

18.3

26.2

500

750

13

1290

18.9

26.2

600

900

16.2

1540

22.7

27.6

700

1050

18.6

24.5

37.2

800

1200

18.6

28.3

43.8

900

1350

20.0

30.2

48.3

1000

1500

22.9

33 2

52.6

5000

5000

key word:

Get a quote