Fiberglass sand filled pipeline

- Commodity name: Fiberglass sand filled pipeline

- Detailed description

-

Product Description

The fiberglass pipes produced by our company meet the relevant Chinese standards and industry standards such as National Building Materials (JC/T838), Urban Construction (CJ/T3079), Chemical (HG20520), Electric Power (DL/T802), Coal (MT181), and can also meet international standards such as ANST/AWWAC950, ASTMD3517, BS 5480, etc. Pipes with a nominal diameter less than 300mm and a design pressure greater than or equal to 1.6MPa and a design stiffness less than or equal to 5000Pa are generally sand free fiberglass pipes, commonly referred to as process pipes (see JC/T552 standard for details). Select high-quality resins, fibers, and accessories to make high-quality pipelines. The production and processing of the product adopts a microcomputer controlled high tension cross winding process, which can use two sanding methods: upper and lower.

Product Features

1. Multi layered structure - strong designability

Compared with traditional and new pipes, it is possible to meet the requirements of different pressures, stiffness, and other complex stress conditions by adjusting the number of glass fiber circumferential and cross winding layers, winding angles, and sand layer thickness, resulting in high structural efficiency. Choose different matrix materials - resin - to ensure reliable pipes meet the requirements of drinking water, heating, flame retardancy, anti-static, and corrosion resistance to special media.

2. Lightweight - convenient transportation and installation, low cost

The density of the pipe is only (1.7~1.9) g/cm3, and the unidirectional fiber tensile strength can reach 1000MPa; The installation cost is less than 60% of traditional pipes, and the installation joints can be tested individually for safety and reliability.

3. Smooth inner wall - low energy consumption

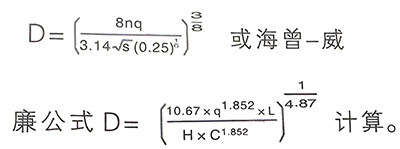

The roughness coefficient n ranges from 0.0079 to 0.0084, the Haizeng Wilhelmshaven roughness coefficient C=150, the absolute roughness △=0.05mm, and the roughness remains unchanged after long-term use. At the same pressure and flow rate, the pipe diameter is only 1/1.17 of that of traditional pipes. The selection of pipe diameter can be referred to

Manning's formula:

4. Corrosion resistance - long service life and low maintenance costs

Excellent corrosion resistance is the foundation of long service life, and the 50 year HDB and Sb design benchmark values are the guarantee of long service life. After the normal use of buried pipelines, there is no need for maintenance. Taking six examples of pipelines with a diameter of 800, only anti-corrosion fees can be saved by 60000 yuan per kilometer.

Applications

(1) Drinking water transportation

(2) Sewage treatment

(3) Seawater transportation

(4) Power plant circulating water pipe

(5) Transport of chemically corrosive media

(6) Agricultural irrigation for oil and gas transmission

Technical ParameterNominal stiffness 2500Pa Stiffness 3750Pa Stiffness 5000Pa Stiffness 7500Pa Stiffness 10000Pa Stiffness Nominal pressure

/Thickness

/Diameter0.25MPa 0.6MPa 1.0MPa 0.25MPa 0.6MPa 1.0MPa 0.25MPa 0.6MPa 1.0MPa 1.6MPa 0.25MPa 0.6MPa 1.0MPa 1.6MPa 0.25MPa 0.6MPa 1.0MPa 1.6MPa 300 5.00 5.00 5.00 5.00 5.00 5.00 5.40 5.30 5.30 6.10 6.10 6.00 5.80 6.70 6.70 6.50 6.30 400 5.70 5.70 5.50 6.30 6.30 630 6.80 6.80 6.60 8.00 8.00 7.50 7.40 8.50 8.70 8.30 8.10 500 6.90 6.70 6.60 7.70 7.70 7.50 8.50 8.40 8.00 9.70 9.50 9.10 8.80 10.70 10.50 10.10 9.80 600 8.20 7.70 7.70 9.20 9.10 8.50 10.20 9.70 9.30 11.50 11.40 10.70 10.50 13.00] 12.40 11.70 11.50 700 9.50 8.80 8.60 10.80 10.30 10.00 12.00 11.30 10.70 13.60 13.00 1,240 11.90 15.20 14.50 13.50 13.10 800 10.90 10.20 9.90 12.40 11.50 11.00 13.70 13.20 12.10 15.80 14.70 14.00 13.50 17.50 17.00 15.20 14.80 900 12.20 11.40 10.80 14.00 12.90 12.30 15.50 14.40 13.50 17.90 16.90 15.60 15.10 19.80 18.60 17.10 16.60 1000 13.50 12.40 11.90 15.60 14.20 13.50 17.30 16.00 14.90 20.00 18.50 17.30 16.50 22.20 21.00 18.80 18.20 1200 16.00 14.70 14.00 18.50 16.80 16.20 21.00 19.10 17.80 23.70 22.00 20.30 19.70 26.30 23.60 22.40 21.60 1400 18.20 17.00 16.00 21.50 19.60 18.50 24.00 22.00 20.30 27.40 25.40 2,340 22.60 30.50 27.50 26.40 25.20 1600 21.30 19.20 18.30 24.10 22.20 21.00 27.60 24.80 23.00 22.40 31.30 29.00 26.60 25.80 34.60 31.20 29.80 28.40 1800 23.30 21.50 20.50 27.20 25.00 23.50 30.80 27.60 25.80 25.20 35.00 32.40 29.90 29.00 39.00 35.00 33.10 31.40 2000 25.90 24.00 22.50 30.00 27.50 26.00 34.00 30.50 28.50 27.70 38.70 36.00 33.00 31.80 43.00 38.60 36.60 34.80 2200 28.50 26.10 24.70 32.80 30.00 28.50 37.00 33.50 31.20 30.40 43.00 39.30 36.20 35.00 47.10 42.30 40.20 38.10 2400 31.10 28.40 26.80 36..00 32.80 30.90 40.30 36.40 34.00 33.20 46.20 42.80 39.20 38.00 51.50 46.20 44.00 41.50 2600 34.00 30.70 29.00 39.00 35.20 33.40 44.00 39.40 36.50 35.80 50.40 48.00 42.40 41.20 55.70 50.00 47.50 45.50

key word:

Get a quote