Fiberglass tank

- Commodity name: Fiberglass tank

- Detailed description

-

Fiberglass storage tank is a type of fiberglass product, which is mainly made of a new composite material using fiberglass as the reinforcing agent and resin as the adhesive through microcomputer controlled machine winding.

Classification

Fiberglass storage tanks can be divided into vertical tanks, horizontal tanks, fiberglass tanks, chemical tanks, anti-corrosion tanks, hydrochloric acid tanks, sulfuric acid tanks, food tanks, fermentation tanks, transportation tanks, storage tanks, glue tanks, chemical tanks, pressure tanks, soy sauce tanks, nitric acid tanks, etc.

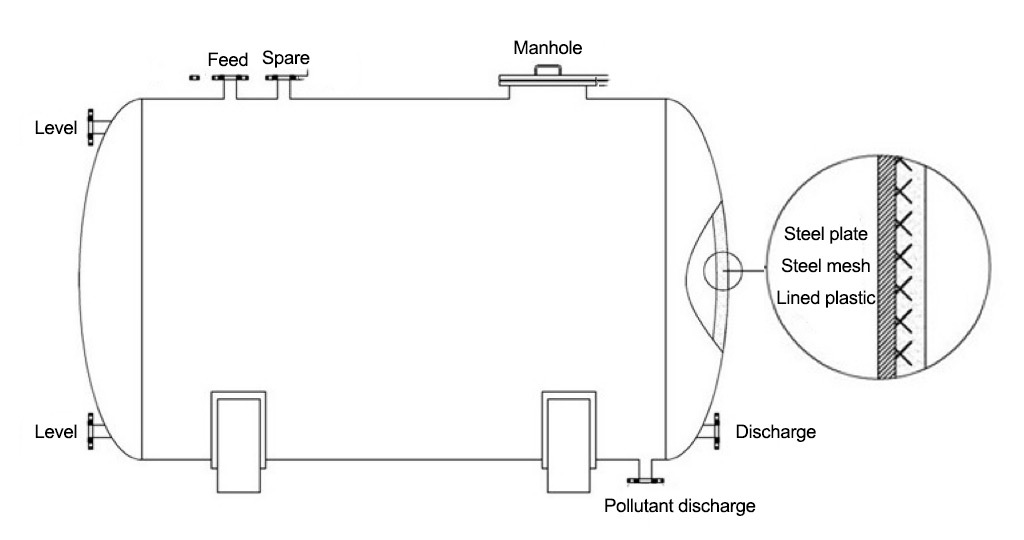

Product Composition

According to the medium used for storage or transportation, epoxy furan resin, modified or polyester resin, and phenolic resin are selected as binders, consisting of a high resin content corrosion-resistant inner lining layer, anti-seepage layer, fiber winding reinforcement layer, and outer protective layer.

Characteristic

(1) Lightweight and high-strength

The relative density ranges from 1.5 to 2.0, which is only 1/4 to 1/5 of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, and the specific strength can be compared with high-grade alloy steel. Therefore, it has excellent results in aviation, rockets, spacecraft, high-pressure vessels, and other products that require weight reduction applications. The tensile, bending, and compressive strength of certain epoxy FRP can all reach above 400Mpa.

(2) Good corrosion resistance

FRP is a good corrosion-resistant material that has strong resistance to atmospheric, water, and general concentrations of acids, alkalis, salts, as well as various oils and solvents. It has been applied in various aspects of chemical anti-corrosion and is replacing carbon steel, stainless steel, wood, non-ferrous metals, etc.

(3) Good electrical performance

It is an excellent insulation material used to manufacture insulators. It can still protect good dielectric properties at high frequencies. Microwave has good transmittance and has been widely used in radar radomes.

(4) Good thermal performance

FRP has a low thermal conductivity, ranging from 1.25 to 1.67 kJ/(m • h • K) at room temperature, only 1/100 to 1/1000 of metal, making it an excellent insulation material. Under instantaneous ultra-high temperature conditions, it is an ideal thermal protection and ablation resistant material that can protect spacecraft from high-speed airflow erosion above 2000 ℃.

(5) Good designability

① Various structural products can be flexibly designed according to needs to meet usage requirements, which can make the product have good overall integrity.

② Materials can be fully selected to meet the performance of the product, such as designing products that are corrosion-resistant, resistant to instantaneous high temperatures, have particularly high strength in a certain direction, have good dielectric properties, and so on.

(6) Excellent craftsmanship

① The molding process can be flexibly selected based on the shape, technical requirements, purpose, and quantity of the product.

② The process is simple and can be formed in one go, with outstanding economic benefits, especially for products with complex shapes and difficult to form in small quantities, highlighting its technological superiority.

Scope of Use

1. The application industries of fiberglass storage tanks include black metallurgy, non-ferrous metallurgy, power industry, coal industry, petrochemical industry, chemical industry, electromechanical industry, textile industry, automobile and motorcycle manufacturing industry, railway industry, shipbuilding industry, construction industry, light industry, food industry, electronics industry, postal and telecommunications industry, culture, sports and entertainment industry, agriculture, commerce, medicine and health industry, as well as military and civilian applications.

2. The media that fiberglass storage tanks can store:

(1) Inorganic acids: (dilute sulfuric acid, dilute nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, hydrobromic acid, hypochlorous acid, silicic acid, nitrite, sulfite, carbonic acid, fluorosilicic acid, fluoroboric acid, etc.).

(2) Organic acids: (formic acid, acetic acid, propionic acid, butyric acid, lauric acid, fatty acid, lactic acid, glycolic acid, peracetic acid, oxalic acid, malonic acid, succinic acid, maleic acid, malic acid, tartaric acid, benzoic acid, etc.).

(3) Alkalis and hydroxides: (Sodium hydroxide, potassium hydroxide, ammonia hydroxide, calcium hydroxide, magnesium hydroxide, barium hydroxide, aluminum hydroxide, iron hydroxide, ammonium sulfate, ammonium nitrate, ammonium carbonate, ammonium nitrate, ammonium phosphate, ammonium persulfate, ammonium chloride, sodium silicate, potassium hypochlorite, aluminum carbonate, aluminum nitrate, aluminum sulfate, potassium acetate, potassium formate, potassium, copper sulfate, copper nitrate, alum, calcium carbonate, etc.).

(4) Elements, gases, and other inorganic compounds (sulfur, sulfur colloids, phosphorus, mercury, hydrogen peroxide, ammonia, coal, carbon monoxide, carbon dioxide, sulfur dioxide, hydrogen chloride, hydrogen bromide, hydrogen sulfide, phosphine, boron fluoride, calcium oxide, zinc oxide, etc.).

(5) Alcohols, aldehydes, ketones, ethers, esters, hydrocarbons, and petroleum products (methanol, ethanol, n-propanol, isopropanol, dilute propanol, butanol, sec-butanol, tert butanol, n-ethanol, tert ethanol, formaldehyde, acetaldehyde, butanal, asphalt, etc.).

(6) Other elemental compounds, industrial liquids and products, food and vegetable oils, atmosphere, water, soil (soap, detergent, sulfur lime, bleach, ink, latex, starch, gelatin, animal oil, rosin, nicotine, vinegar, yeast, wine, seawater, brine, high-purity water, acidic mineral water, sewage, soil, etc.).

(7) Organic compounds containing halogens, amines, phenols, and other organic compounds (such as chloropropanol, chloramine, hexachlorobenzene, Freon, dimethylformamide, resorcinol, hydroquinone, sodium phenolate, nicotine, etc.).

Taking chemical storage tanks and pipelines as an example

We have laid the foundation for global companies by manufacturing and supplying a range of fiberglass reinforced plastic chemical storage tanks and pipelines. Over the past 16 years, these storage tanks have been proven to be sturdy and durable in the harshest and most corrosive environments. Our fiberglass chemical storage tanks, pipelines, and containers are renowned for their reliability and cost-effectiveness. Our fiberglass chemical storage tanks are used to store chemicals such as sodium hypochlorite, sodium hydroxide, aluminum sulfate, silica, coagulants, and iron oxide. Collaborating with world leading resin manufacturers and advanced technology providers, Colin selects the most suitable resin system for the required applications. FRP tanks are manufactured using the most advanced and innovative technology, with excellent corrosion resistance, and have been tested and verified under the most severe conditions. FRP chemical storage tanks can be designed according to customer requirements for atmospheric pressure, vacuum or positive pressure and undergo strict testing. Our engineers will consider differences in process design during the engineering phase based on the specific requirements of the client. FRP tanks and pipelines can be constructed in various configurations and designed and manufactured in accordance with AS2634-1983, BS4994-1987, and ASME RTP-1-2011. KELIN provides unique chemical storage tank and pipeline manufacturing services.

key word:

Get a quote